[Reprint] Southern Client | Contes: Building the Fastest Rapier Loom in China

On May 30, "Southern Client" published a report entitled "Contes: Building the Fastest Rapier Loom in China | Gaoming Industry Research ④" introducing Jinde Loom. The following is the full text.

Walking into the office building of Guangdong Kangtes Weaving Equipment Co., Ltd. (hereinafter referred to as "Kangtes"), a landscape painting of "Welcome Pine" is brightly colored and lifelike. A closer look shows that the painting is not actually painted on it, but a piece of cloth woven on a smart Jacquard loom of Contes.

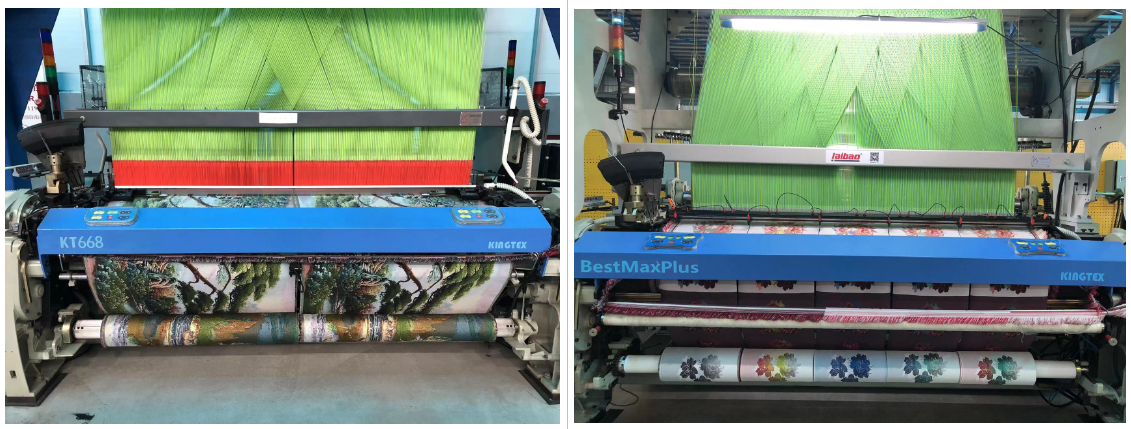

Start the loom, transfer the picture to the computer, adjust the color through programming, and then a picture can be "generated with one click" like 3D printing ". "KT668 high-speed rapier jacquard loom is mainly aimed at the production of home textile products. It is mainly sold to Zhejiang and exported to India. As long as textiles with patterns on them can be produced by this machine." Huang Shu, director of the general manager's office of Contes, said.

Kangtus is located in Gaoming District, Foshan City, focusing on the research and development, production, sales and technical services of intelligent weaving equipment. It is a key enterprise in China's textile machinery industry. It is currently the executive director unit of Guangdong Textile Association and the vice president of China Textile Machinery Association. It has won many honors, such as national high-tech enterprise, Guangdong "specialized and special new" enterprise, Guangdong strategic emerging industry cultivation enterprise, Foshan sub-industry leading enterprise, Foshan invisible champion cultivation enterprise, and Foshan invisible champion cultivation enterprise.

At present, Contes has obtained more than 50 authorized patents/copyrights, and its product technology has reached the domestic leading and international advanced level. Its products rank among the top three in the domestic market and are exported overseas.

GUANGDONG CONTERS WEAVING EQUIPMENT CO., LTD. Enterprise drawing

A "welcome pine" landscape painting bright colors. Shooting by Zhu Sujiao

800 turns a minute.

The speed of high-speed rapier loom is the fastest in China.

Kanters's only trademark brand "Jinde KINGTEX" has a wide range of visibility in the industry, and has been recognized as a famous trademark of Guangdong Province and a famous brand product of Guangdong Province.

Entering the product display area of Contes, KT800 high-speed rapier loom, KT668 high-speed rapier jacquard loom and other advanced products are placed in an orderly manner, with high degree of intelligence, simple startup operation, and one person can operate multiple devices.

The product display area of Contes. Shooting by Zhu Sujiao

For the loom, the higher the rotation speed means the faster the weaving speed and the higher the production efficiency. In order to meet the different needs of the market and enhance the core competitiveness of enterprises, since 2016, Kanters has invested in independent research and development of high-speed rapier looms. In October 2018, KT800 high-speed rapier loom made its debut at the Shanghai International Textile Machinery Exhibition, becoming the fastest model among the rapier looms participating in the exhibition at a speed of 800 r/min. KT800 quickly gained a reputation in the industry.

It is worth mentioning that the core components and key control systems of KT800 are independently developed by CONTEX, and have obtained invention patents and utility patents.

"As far as we know, KT800 is currently the fastest rotating speed in the domestic market. Compared with the mainstream models on the market, the unit production capacity of KT800 can be increased by about 10% ~ 15%, which can help enterprises reduce energy consumption and improve production efficiency." Huang Shu said that currently Contes has more than 400 orders in hand, of which KT800 orders have been placed until September.

KT800. Photographed by Zhu Sujiao

At present, Kanters takes rapier looms as its leading products, with complete models and specifications, including jacquard looms, towel looms, industrial cloth looms, trademark looms, etc., and the fabric scope covers clothing, home textiles, industrial cloth, etc. In the field, the domestic market share ranks among the top in the industry. The products are mainly sold to major domestic textile industry clusters such as Guangdong, Guangxi, Jiangsu, Zhejiang, and exported overseas.

Emphasis on R & D

The core technology in their own hands

For long-term development, enterprises must take the road of technological innovation and establish their own brands. As early as more than 10 years ago, Contes moved from the initial imitation of foreign products to the road of independent innovation, investing 4% of its revenue in research and development every year, focusing on the research of intelligent weaving equipment technology.

After years of innovative research and development, Contes has obtained more than 50 authorized patents/copyrights, and its product technology has reached the domestic leading and international advanced level. As the main drafting unit, it has participated in the formulation of a number of technical standards, for example, the industry standard-"flexible rapier loom" (FZ/T94004-2009), the national standard-"stop rod for textile machinery and accessory electronic stop devices" (GB/T 38417-2019), and the industry standard-"technical conditions for textile machinery and accessory roll rolls" (FZ/T 92083-2023). Currently participating in the development of industry standards-"Towel Rapier Loom" (plan No. 2022-1060T-FZ).

In 2022, despite the impact of the epidemic, but Contes did not stop the pace of research and development, but against the trend to increase research and development efforts, the development of chemical fiber looms, steel wire looms and other new technology products, the layout into the industrial cloth special fabric market. Kangtus is the supporting unit of Guangdong Enterprise Technology Center, Guangdong Engineering Technology Research and Development Center and China Textile Machinery Industry Rapier Loom Product Research and Development Center. Dai Xiaohan, general manager and chief engineer of Kangtes, who is active in the front line of the workshop, has more than 30 years of technical research and development experience in the field of weaving. He is a well-known expert in the industry. He is currently the vice president of the China Textile Machinery Association and the weaving machinery and equipment group of the China Textile Engineering Society. leader.

In the Kangtes assembly workshop, at a glance, dozens of intelligent loom products are arranged in an orderly manner, some have been assembled, some are in the process of assembly. Shooting by Zhu Sujiao

Contes has been committed to the core, critical technology in their own hands. "For example, the control system used to be developed by an industrial control software company. Now we have also invested in independent research and development and are trying it out with customers." Huang Shu said that the newly developed control system can achieve the effect of machine networking. For example, if a customer purchases a batch of equipment, as long as there is a network, he can rely on the system platform to connect all machines and build a digital factory.

Huang Shu said that Contes insists on taking technological innovation as the leader, and continuously improves the technical level of products in accordance with the concept of "application generation, R & D generation, and reserve generation. "For example, the KT800 is already the most advanced machine on the market, but we are already developing more advanced technology." In November this year, Contes will participate in the China International Textile Machinery Exhibition and ITMA Asia in Shanghai to display the latest products.

Digital power

Renovation of the second-phase plant to increase production capacity

For the future development of the industry, Huang Shu is very confident. The textile industry is a traditional industry, but the traditional does not mean the sunset. The first meeting of the 20th Central Finance and Economics Committee emphasized: Persist in promoting the transformation and upgrading of traditional industries, and cannot simply withdraw as a "low-end industry. This news also makes Huang Shu more confident that the textile industry will continue to develop in the future.

In order to improve production efficiency and improve product quality, Contes continues to promote the digital transformation and upgrading of the factory. In the Kantes machining workshop, a number of intelligent precision machining centers are operating at high speed. "Relying on the precision machining center, some key components of the company and components that need technical confidentiality are now processed and produced independently to ensure the safety of supply." Huang Shu said that it is precisely because of the improvement of the ability of independent processing that Contes has effectively improved the processing accuracy and supporting efficiency, and the production efficiency has increased by 10% to 20%.

In the Kantes machining workshop, several intelligent precision machining centers are operating. Cantus

A few days ago, Contes held a digital project launch conference. Huang Shu said that the digital project is mainly to improve the digital management level of the factory by optimizing and upgrading the online MES, WMS, SRM and other management systems.

In order to expand production capacity, Kanters plans to invest tens of millions of yuan to transform the second phase of the plant, which covers an area of nearly 20000 square meters. Huang Shu revealed that the construction of the second phase of the plant is expected to be completed in the first half of next year, and the production capacity of Contes can be increased by 30% ~ 40% after it is put into operation.

Source: South + Client

RELATED INFORMATION

Invitation | Asean Textile New Trends ᛫ Saigon Tex 2025 will be impending opening!

2025-04-07

Build a fashionable and personalized fabrics by Warp Heat Transfer Printing Machine On The Loom

2025-02-19

No.5 Yingchun Road, Yanghe Town, Gaoming District, Foshan City, Guangdong Province

Copyright © Guangdong kingtex weaving equipment Co., Ltd