The first 6S knowledge competition of Jinde loom has come to an end.

On the afternoon of September 14, the first 6S knowledge competition of Guangdong kants weaving equipment co., ltd came to an end in the intense final. A total of 15 teams from various departments of the company participated in the competition. after a fierce group preliminary competition, the six finalists competed in a showdown on the 14th, and finally the new star team from the technology research and development system stood out and won the crown.

This activity is carried out through a competition of entertaining and entertaining, aiming to further promote the continuous development of 6S management and strengthen the awareness of all staff to participate in 6S.

The competition is carried out in a rush-to-answer manner, including three types of questions: judgment questions, multiple-choice questions and fill-in questions. The first match started on August 24 and lasted more than 20 days.

Speech by Zeng Wei, Deputy General Manager of Guangdong Kangtes Weaving Equipment Co., Ltd.

With solid theoretical knowledge, the contestants continue to score points for their respective teams. During the competition, the players not only had to fight for speed, but also for courage. The atmosphere was tense and warm.

During the competition, the third-party consulting teacher commented on the competition on the spot.

Live cheerleaders cheer for the competition team

Since the relocation to the new Gaoming factory in July 2021, in order to further improve the level of on-site management and the quality of Jinde looms, Kantes has introduced third-party consulting management and systematically carried out 6S management projects to carry out fixed, standardized and standardized management of production workshops, warehouses, dining halls and other workplaces. After more than a year of 6S implementation, the management level of each site of the new factory has been greatly improved, and the quality and work efficiency of employees have also been gradually improved, further ensuring the quality of products.

6S standard series training

6S standard series training

Discussion on Perfecting and Optimizing 6S System

Discussion on Perfecting and Optimizing 6S System

Weekly routine inspection

Weekly routine inspection

Eliminate on-site safety hazards

Eliminate on-site safety hazards

On-site discussion on optimizing material placement

On-site discussion on optimizing material placement

Ensure the health and safety of dining in the factory area.

Ensure the health and safety of dining in the factory area.

Make concerted efforts to protect materials

Make concerted efforts to protect materials

Shelves are dust-free and materials are placed neatly

Shelves are dust-free and materials are placed neatly

Neat office desktop

neat cup of water

Parts placed in good order

Parts placed in good order

Cleaning tool location management

Cleaning tool location management

Put every part carefully

Put every part carefully

Professional, the pursuit of excellence, Jinde people are always in action!

RELATED INFORMATION

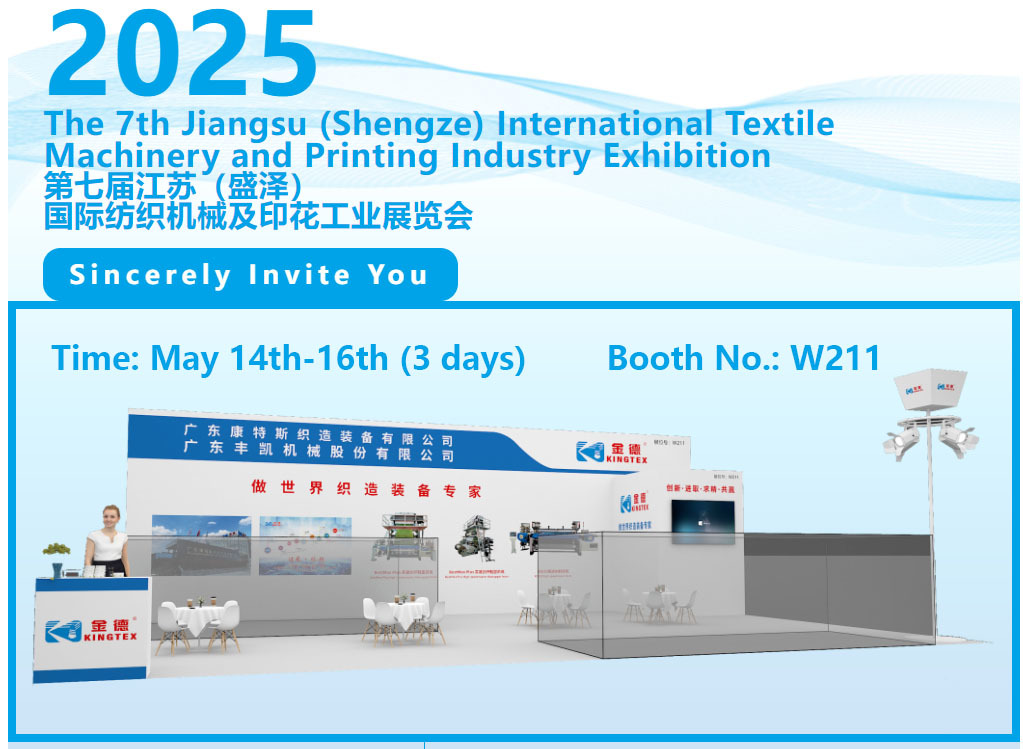

Invitation | Sincerely invite you to join our Booth W211 to appreciate the charm of weaving machines

2025-05-10

KT668-680CM Industrial Fabric Ultra-wide Rapier Loom Machine

2025-04-24

No.5 Yingchun Road, Yanghe Town, Gaoming District, Foshan City, Guangdong Province

Copyright © Guangdong kingtex weaving equipment Co., Ltd