Build a fashionable and personalized fabrics by Warp Heat Transfer Printing Machine On The Loom

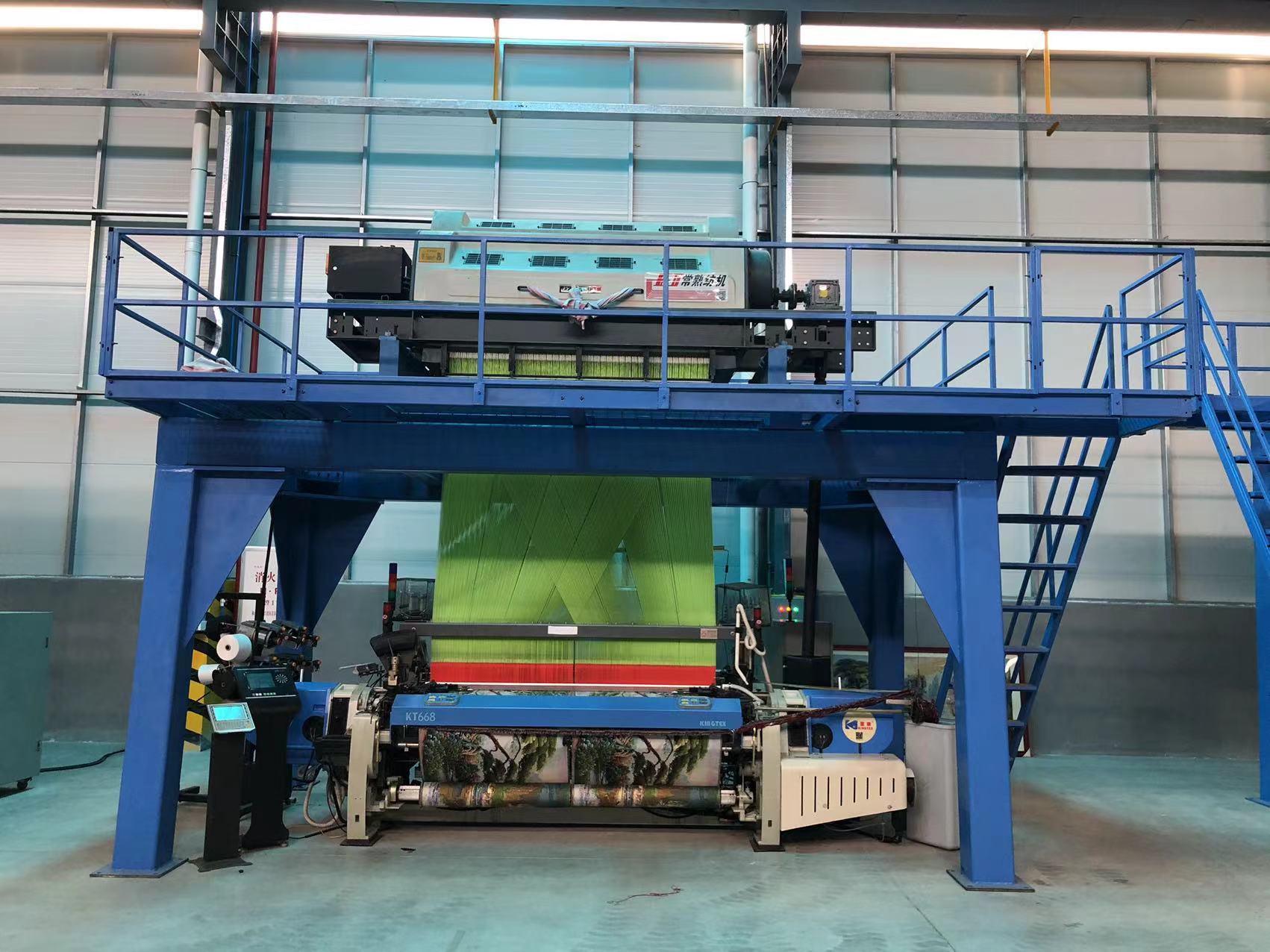

With the vigorous development of the textile industry, fashionable and brightly colored fabrics are increasingly favored by the market. In order to meet the diversified needs of consumers, the innovation of loom technology has become the focus of the industry. Recently, a new type of Warp Heat Transfer Printing Machine On The Loom with its unique process has become a leading trend in the industry.

|  |

At present, the traditional jacquard loom has certain limitations in producing fashionable colored fabrics that cannot perfectly combine rich and changeable color styles. The advent of this new type of Warp Heat Transfer Printing Machine On The Loom has solved this problem in the industry.

Traditional Jacquard Loom |  Warp Heat Transfer Printing Machine On The Loom |

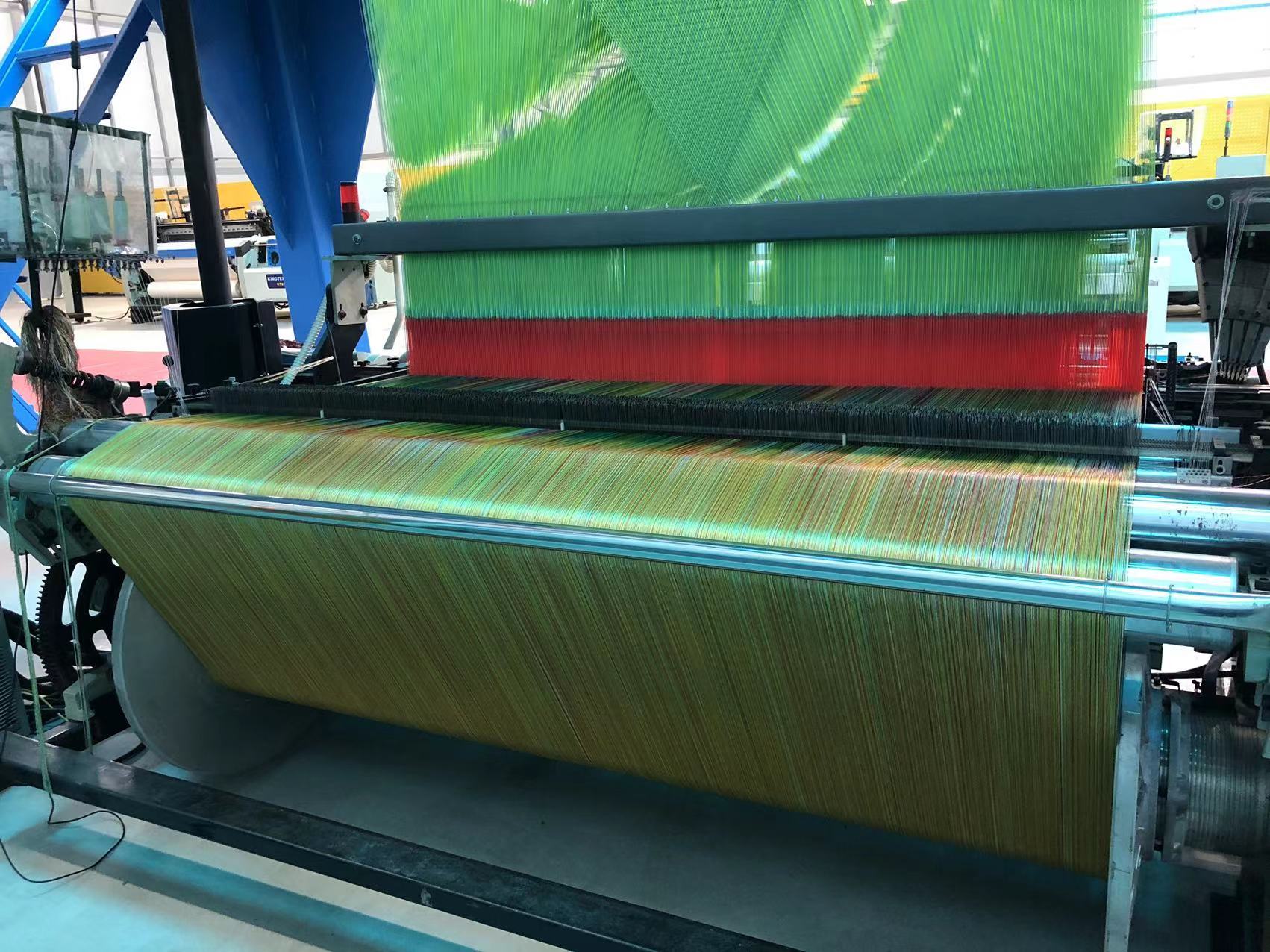

Through the unique process of warp heat transfer printing, the Warp Heat Transfer Printing Machine On The Loom greatly enriches the style of the fabric, build the effect of gradual changes, and greatly enhances the feeling of fabric layering. The use of this technology not only improves the overall beauty of the fabric, but also gives a new insight into the practical characteristics.

Flat Color, No Gradient, No Textured |  Vivid Color, Gradient Effect, Textured Fabric |

Compared with the traditional jacquard loom, which first dyes warp yarn before weaving, the Warp Heat Transfer Printing Machine On The Loom can do coloring for warp yarn during weaving. Combined with loom programming, the color position of each warp yarn can be precisely adjusted to form complex patterns such as gradual variation, geometry, and abstraction. By adjusting the density of the warp, the structure of the weave (for example, plain, twill, jacquard) in combination with colored warp yarns to enhance the three-dimensional and tactile level of the fabric. And color changing is more flexible, more environmentally friendly, more economical, supports small-scale production, users can enter custom pattern code or select a parametric design template, quickly creating an exclusive fabric.

First dyes warp yarn before weaving |  Colored for warp yarn by heat transfer printing machine during weaving |

With the growing diversified demand in today's market, the advent of a new type of Warp Heat Transfer Printing Machine On The Loom has bring a new impetus to the textile industry. The continuous progress and improvement of this technology indicates that the textiles of the future will be more colorful and more responsive to the individual needs of consumers.

Kingtex Weaving Machines,Textile Machinery Manufacturer,Rapier Loom Supplier,Warp Heat Transfer Printing Machine On The Loom,Jacquard Loom

Next:

RELATED INFORMATION

2026-02-17

Notice | 2026 Spring Festival Holiday

2026-02-12

Spring Forward with Momentum | Kingtex 2025 Annual Gala “Ride Into a New Journey” Successfully Held

2026-02-11

No.5 Yingchun Road, Yanghe Town, Gaoming District, Foshan City, Guangdong Province

Copyright © Guangdong kingtex weaving equipment Co., Ltd