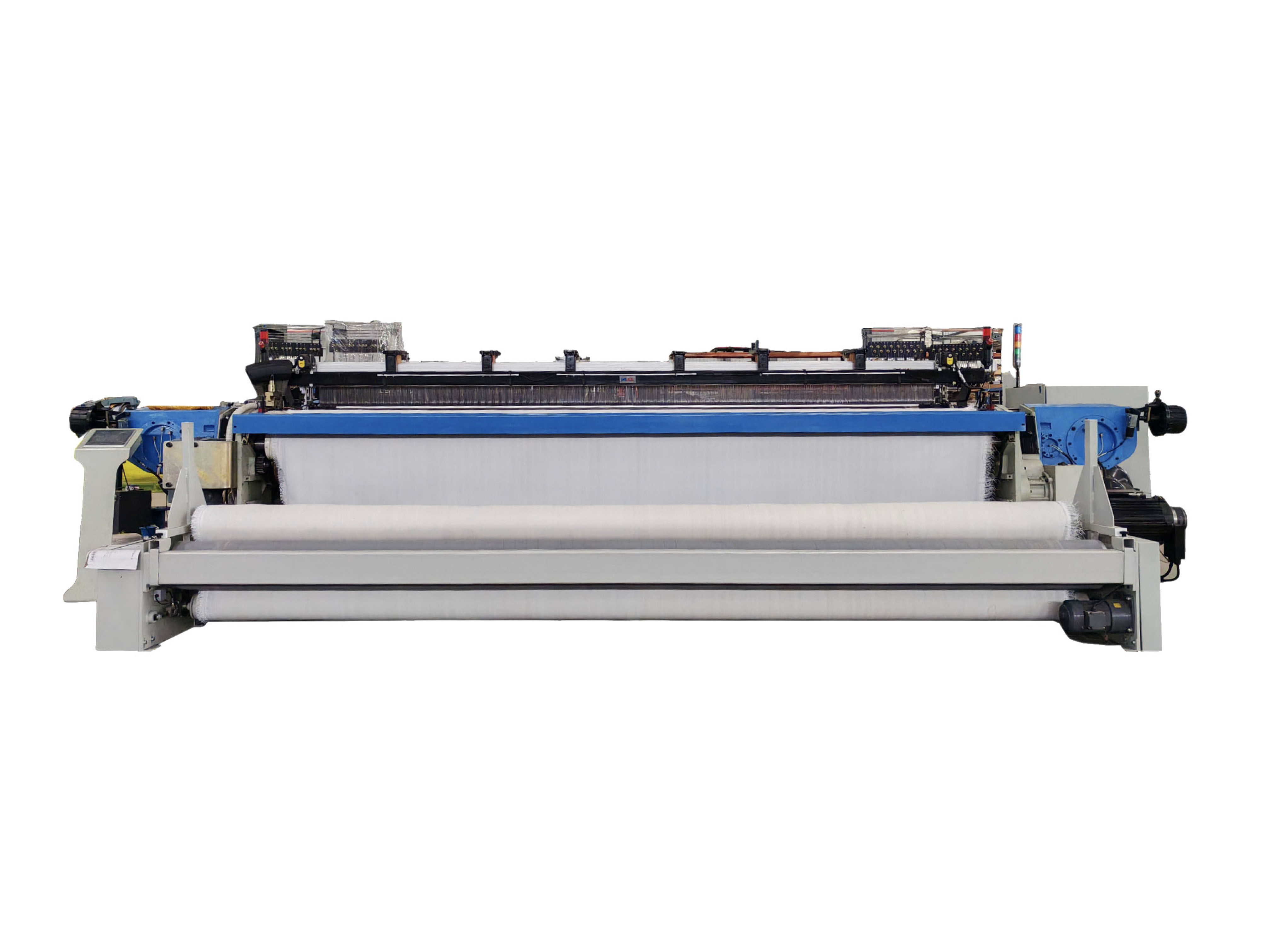

FastMax High Speed Rapier Loom

Leveraging advanced super motor direct drive technology,this product achieves internationally competitive performance standards.Equipped with multiple patented innovations,it delivers exceptional cost-performance value,an intuitive human-machine interface,and streamlined operational workflows.Engineered for maximum production efficiency and remarkably low operating costs,it adapts flexibly to diverse market demands.

Classification:

Rapier Looms

Hotline:

FastMax High Speed Rapier Loom

| Main Drive | According to the actual load output torque, energy saving than traditional looms 20%-30% |

| Weft Insertion | The relay-type weft insertion system utilizes a weft-receiving sword that minimizes tension fluctuations during its return phase. This significantly enhances weft yarn handover reliability while reducing breakage rates to optimal levels. |

| Shedding | Lower electronic dobby shedding, up to 20 heald frames |

| Electrical Control System | The 32-bit microprocessor control system delivers precise, responsive operation. Process parameters are easily configured via panel, USB or wireless input. The system automatically detects loom faults—categorizing and logging them—while continuously collecting operational data from each machine. This enables real-time monitoring of key production metrics (efficiency, output, scheduling), and features comprehensive networking capabilities including group control, remote operation, and online diagnostics. |

| Lubrication Cooling System | Aluminum alloy oil tank, circulating spray lubrication, increase oil temperature sensor, forced water cooling to achieve the purpose of cooling oil temperature. |

| Color Selection | Stepping motor controlled rotary high-speed electronic weft selector, color selection mechanism can be equipped with up to 16 Colors. |

| Pick Finding | According to the characteristics of the fabric, two ways of finding the weft can be used, which are motor type or hydraulic type, to minimize the weft, and at the same time, the electronic adjustment of the opening and leveling time can be realized through the motor type or hydraulic type. |

| Let Off | Servo electronic let-off, digital closed-loop control constant tension weaving, from full shaft to empty shaft tension fluctuation is small. |

| Take Up | Servo electronic coiling, which can realize variable weft density weaving. |

| Heald Frame Connection | The heald frame connection adopts the upper hanging type, and it is convenient to adjust the height of the heald frame and change the variety. |

Previous

Previous

BestMax High Speed Rapier Loom

Online consultation

No.5 Yingchun Road, Yanghe Town, Gaoming District, Foshan City, Guangdong Province

Copyright © Guangdong kingtex weaving equipment Co., Ltd