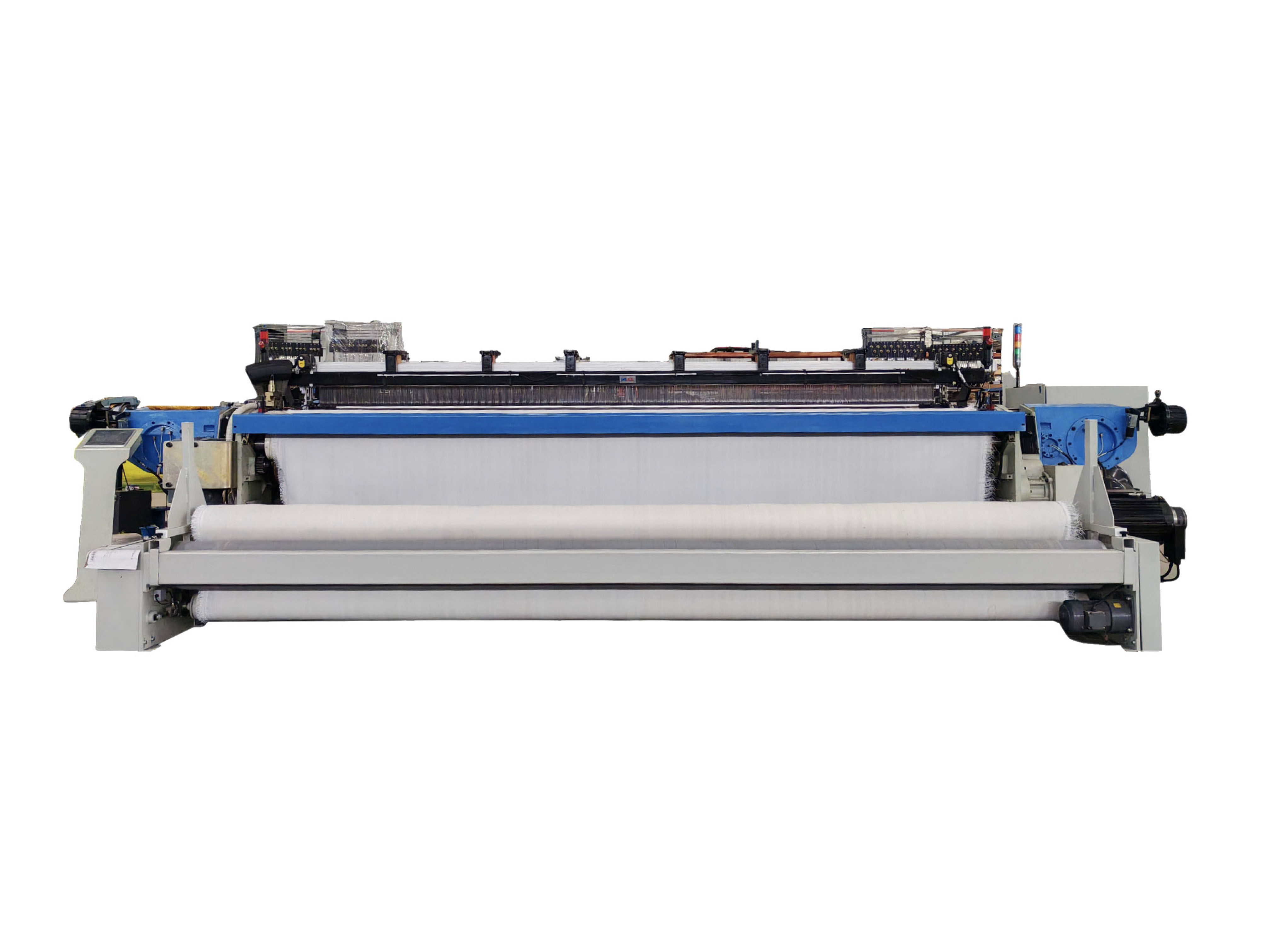

KT668-680CM High Speed Rapier Ultra-Wide Loom

KT668-680CM High-Speed Rapier Ultra-Wide Loom is a high efficiency and intelligence loom special for weaving a wide range of industrial fabrics in different industries, such as: Filter Fabric, Geotextile Fabric, Greenhouse Fabric, Advertising Fabric, Carpet Lining Fabric and other heavy ultra-wide industrial fabric, up to 1000CM.

Classification:

Ultra-Wide Rapier Loom

Hotline:

KT668-680CM High Speed Rapier Ultra-Wide Loom

| Main Drive | Switched reluctance motor is directly driven, according to the actual load output torque size, compared with the traditional loom energy saving 20-30%. |

| Weft Insertion | The space four-bar linkage drives the rapier wheel to move back and forth through the sector gear.The weft is fed from the left side and handover in the middle. It optimizes the dynamic balance of the weft insertion mechanism,reduces the moment of inertia of the weft insertion mechanism,and ensures the high-speed performance of the weft insertion mechanism. |

| Beating Up | Conjugate cam beating up,Separate slay,Strengthen the rigidity of beating up and increase the beating up force. Moving balance is better for high speed weaving. |

| Shedding | Lower Electronic Dobby,with 20 pcs heald frames at most. |

| Let Off | Servo electronic let-off digital closed-loop control constant tension weaving,From full beam to empty beam, the tension fluctuation is small. |

| Take Up | Servo electronic take-up,Variable weft density weaving can be realized. |

| Pick Finding | AUTO pick finding.When weft finding,loom depart with dobby,and Main motor drive the dobby directly,to get an accurate action to find weft then ensure there is no wrong pattern in fabric,helping to eliminate the starting mark. |

| Color Selection | Stepper motor control rotary high speed electronic weft selector, 4-16 colors. |

| Heald Frame Connection | Top-adjust Heald frame linkrod system.Height adjustment entirely can be done above the heald frame,easy for installation.Automatic Heald leveling time adjustment and Automatic Heald leveling function. |

| Electrical Control System | The main servo and host computer adopt Ethercat communication,the whole machine adopt 32-bit CPU microcomputer intelligent control,break warp,break weft,empty weft,multi-weft,positioning stop,automatically detect fault and display fault. The fabric pattern,tension,weft density and other process parameters areinput by the panel or USBinput or wireless input parameters, and according to set parameters operation,stop,output,efficiency and other loom self-statistics,each control work is accurate and sensitive, and can realize theindustrial Internet of things,the cloud monitoring equipment operation and the collection data active upload platform and the on-lineinteligent diagnosis and carries on the alarm push function,the remote debugging program, can be used mobile phones,laptops and other mobile monitoring. |

| Lubrication Cooling System | Drive oil way by single oil pump motor.Closed forced circulation lubrication system and Forced water cooling system, forced lubrication and cooling functions,ensure the machine normal temperature rise. |

| Reed Width | 380cm、400cm、420cm、460cm、480cm、520cm、540cm、680cm、up to 1000cm. |

| Loom Speed | Economic speed 160-220 RPM. |

Previous

None

Next

Online consultation

No.5 Yingchun Road, Yanghe Town, Gaoming District, Foshan City, Guangdong Province

Copyright © Guangdong kingtex weaving equipment Co., Ltd