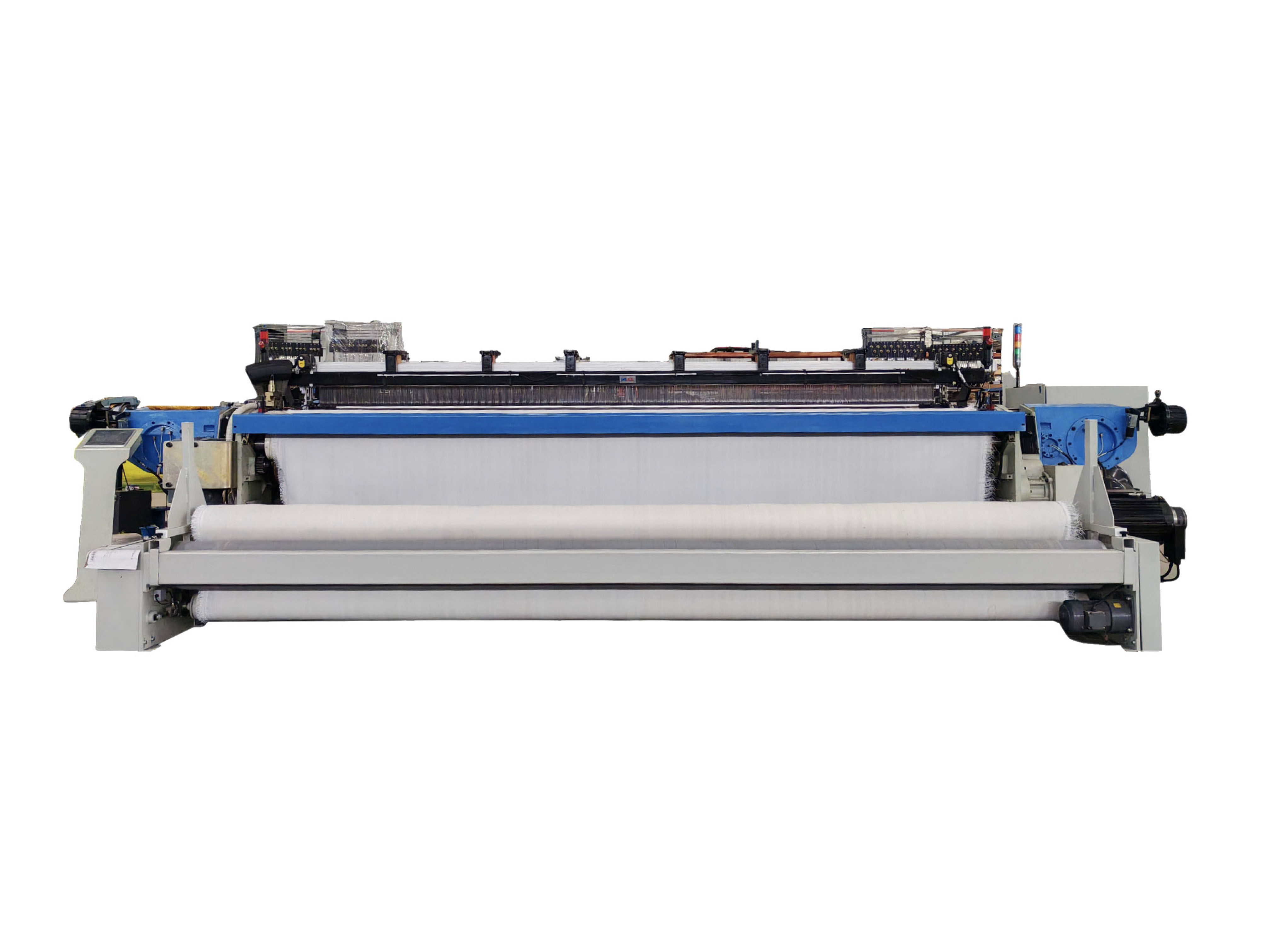

DS300 High Speed Velvet Rapier Loom

DS300 high-speed velvet rapier loom uses advanced mechatronics technology, with mature and stable performance, economic speed of 250-350 r/min, maximum weft insertion rate of 1080 m/min, and original patented cutting technology on single-weave loom, which realizes direct cutting on loom, shortens flannel production process flow, ensures smooth suede and has no cut marks and creases, and is a high-speed intelligent loom with high cost performance.

Classification:

Velvet Weaving Machines

Hotline:

DS300 High Speed Velvet Rapier Loom

| Main Drive | High force energy asynchronous motor drive, the use of frequency converter to achieve stepless speed change. |

| Weft Insertion | Space four-bar linkage drive, single weft insertion device. |

| Beating Up | Double side drive, conjugate cam beating up mechanism. |

| Shedding | Electronic dobby shedding, up20Heddle frame. |

| Electrical Control System | Adopt 32Bit CPU Microcomputer control system, accurate and sensitive control action, process parameters can be panel input,USB Input or wireless input, automatic detection of loom operation failure and classification statistics, automatic collection of each machine operation data, real-time understanding of the machine production situation (efficiency, output, scheduling, etc.), with network group control, remote control, online diagnosis and other functions. |

| Lubrication Cooling System | Closed forced circulation lubrication device, equipped with oil pressure and oil level alarm device. |

| Color Selection | Electronic color selection mechanism can be matched at most8Color. |

| Pick Finding | Idle automatic weft finding. |

| Let Off | Servo electronic let-off, digital closed-loop control constant tension weaving, from full shaft to empty shaft tension fluctuation is small. |

| Take Up | Servo electronic coiling, which can realize variable weft density weaving. |

| On-machine Pile Cutting Device | The original patented technology of cutting pile on the single-weave loom realizes direct cutting pile on the loom, shortens the production process of flannel, and ensures that the suede is smooth without cutting marks and creases. |

| Cashmere Feeder | Optional mechanical lint feeding device or servo electronic lint feeding device. |

Previous

None

Next

Online consultation

No.5 Yingchun Road, Yanghe Town, Gaoming District, Foshan City, Guangdong Province

Copyright © Guangdong kingtex weaving equipment Co., Ltd