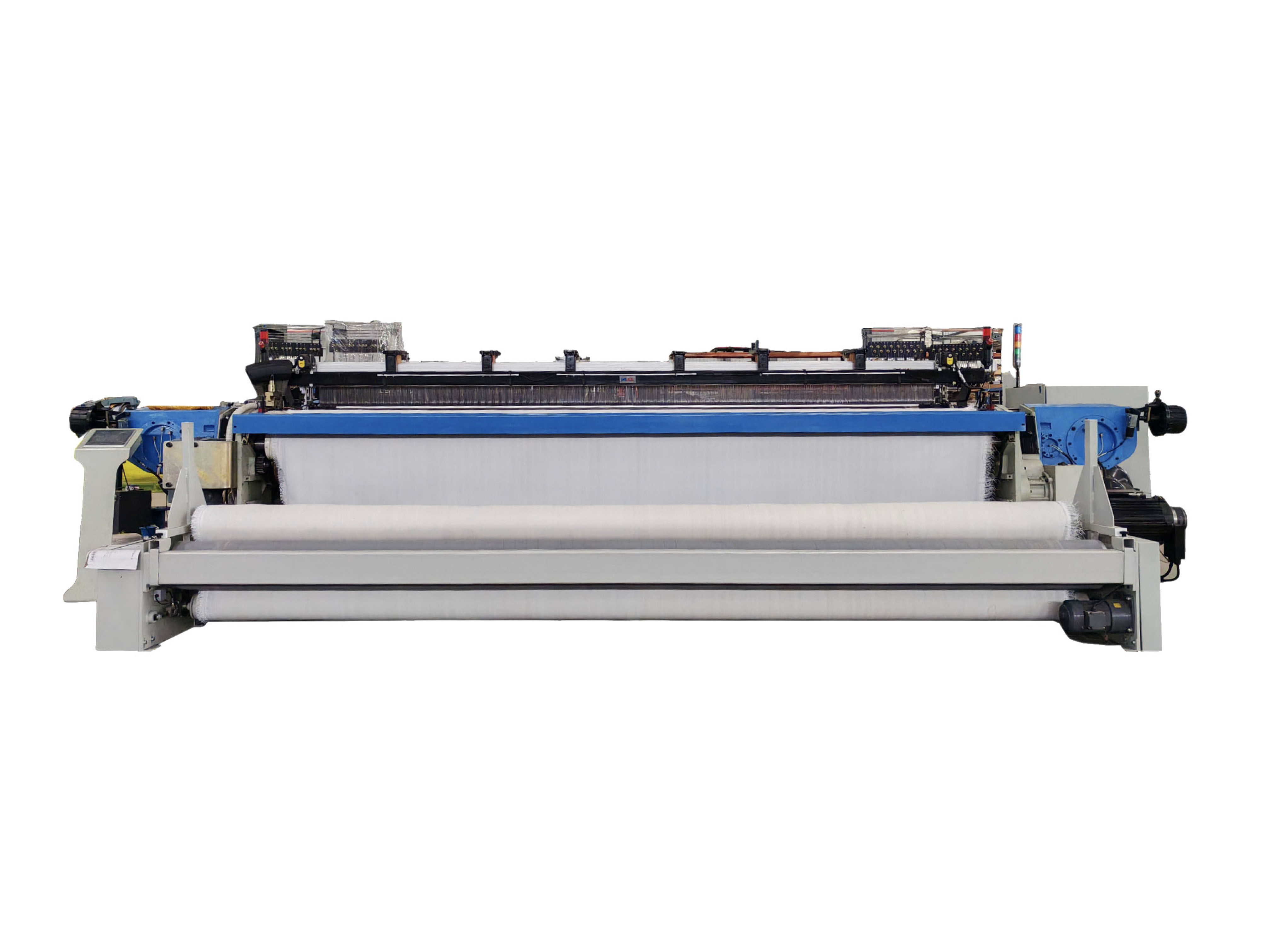

BestMaxJ(A) High Speed Jacquard Rapier Loom

With the perfect function of international mainstream models, with a number of patented technologies, the whole machine technology has reached the domestic leading, international advanced level, with the characteristics of high speed, high efficiency, intelligence and energy saving, bringing high speed and increasing production capacity (ten groups of trademarks) into the ranks of trademarks.

Classification:

Label & Narrow Rapier Looms

Hotline:

BestMaxJ(A) High Speed Jacquard Rapier Loom

| Main Drive | According to the actual load output torque, energy saving than traditional looms20%-30%. |

| Weft Insertion | The weft insertion method adopts a spatial four-bar linkage mechanism, which drives the sword pulley to reciprocate through a sector gear. The left side of the weft supply, the middle of the handover, excellent sword head clip weft way, to ensure the smooth handover of the weft. The narrow sword belt is a suspended hook shuttle; the wide sword belt is a velvet shuttle without a hook. |

| Beating Up | The beating-up mechanism is designed on both sides of the car, which increases the rigidity of the beating-up mechanism, increases the beating-up force and motion balance, and is conducive to high-speed weaving, especially in weaving high-weft dense and heavy fabrics. |

| Electrical Control System | Adopt 32-Bit CPU Microcomputer control system, accurate and sensitive control action, process parameters can be panel input, USB Input or wireless input, automatic detection of loom operation failure and classification statistics, automatic collection of each machine operation data, real-time understanding of the machine production situation (efficiency, output, scheduling, etc.), with network group control, remote control, online diagnosis and other functions. |

| Lubrication Cooling System | A separate oil pump motor drive oil circuit, closed forced circulation lubrication system and forced water cooling mechanism are adopted to ensure normal temperature rise of the machine, ensure good lubrication of all moving parts, and extend the life of the parts. |

| Color Selection | Stepping motor controlled rotary high-speed electronic weft selector, color selection mechanism can be equipped with up16Color. |

| Let Off | Servo electronic let-off, digital closed-loop control constant tension weaving, from full shaft to empty shaft tension fluctuation is small. |

| Take Up | Servo electronic coiling, which can realize variable weft density weaving. |

| Shedding | Electronic jacquard faucet1344,2688Needle optional |

| Thermal Cutting | 6 Section temperature control, intelligent temperature conversion, can quickly raise the knife temperature, set the idle cutting temperature when starting And the function of automatically adjusting the temperature of the cutter when changing speed: that is, when the thickness of the trademark can be automatically set in the weaving stage, the most reasonable cutting temperature to achieve the best cutting quality for precise cutting results. Fully isolated power supply, with higher safety. |

| Heat Setting | Adopt PID Precise temperature control technology. The patented way of shaping the temple can not only ensure a more reasonable setting temperature but also will not damage the product. The ironing board and the temple are designed with energy-saving design. |

Next

Previous

None

Next

Online consultation

No.5 Yingchun Road, Yanghe Town, Gaoming District, Foshan City, Guangdong Province

Copyright © Guangdong kingtex weaving equipment Co., Ltd

Business License