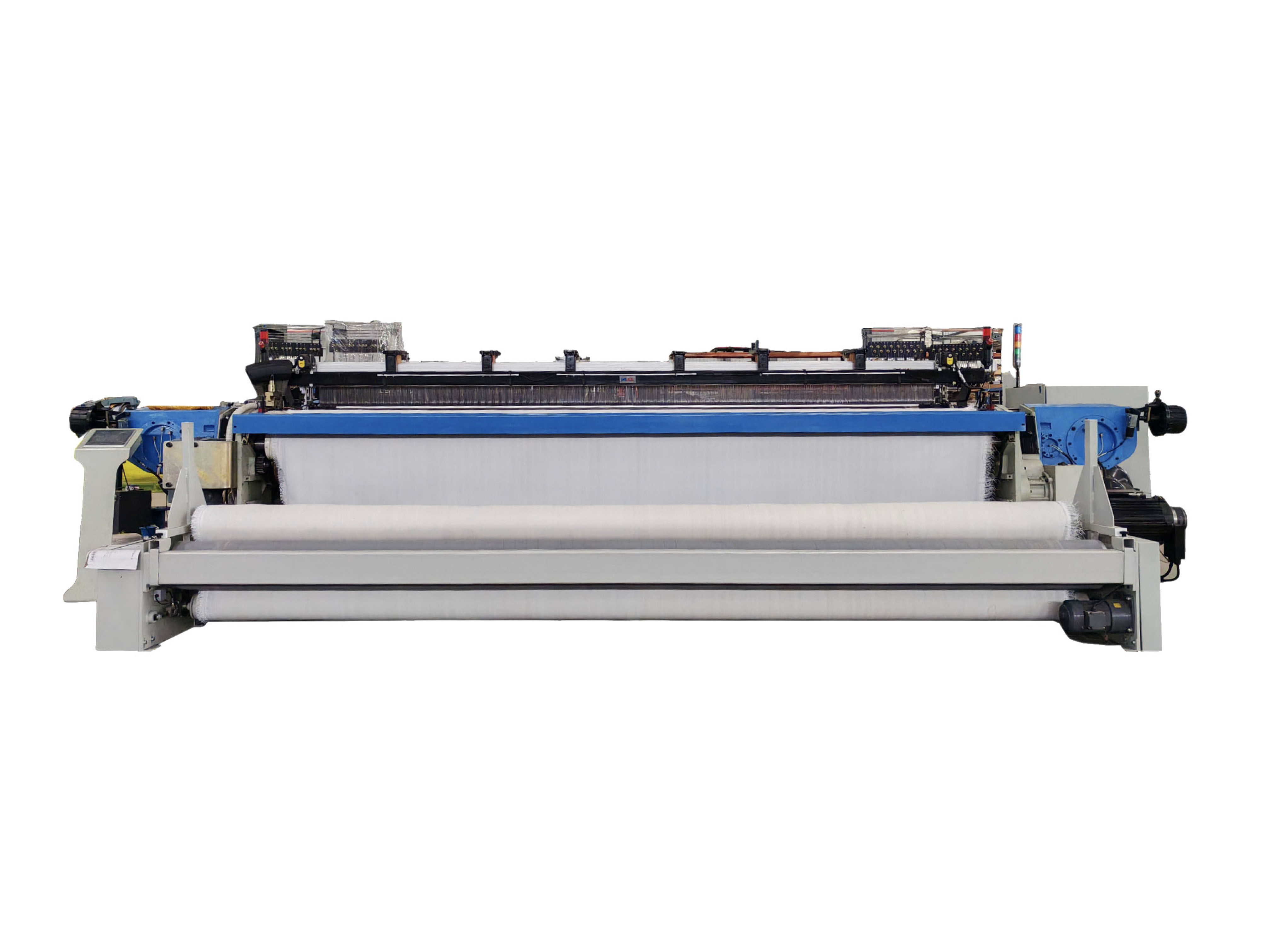

V8M Towel Machine

Product technology has reached the international advanced level, the product has a number of patented technology, its excellent cost performance, perfect man-machine interface, convenient operating environment, the highest production efficiency, very low production cost, can flexibly meet the various needs of the market.

Classification:

Towel Rapier Looms

Hotline:

V8M Towel Machine

| Main Drive | Super servo motor direct drive, according to the actual load output torque size, to achieve the purpose of energy saving and emission reduction. |

| Weft Insertion | Four-axis cross spherical crank weft insertion mechanism, left weft supply, middle transfer, with the best acceleration curve and speed curve, to ensure that the sword head in high-speed state, accurate and stable transfer. |

| Beating Up | The double-sided conjugate cam is used to beat up the weft, and the optimized high-speed cam curve is improved, which reduces the vibration and impact of the beating-up mechanism during high-speed operation. |

| Shedding | Electronic jacquard faucet opening. |

| Electrical Control System | Adopt 32-Bit CPU Microcomputer control system, accurate and sensitive control action, process parameters can be panel input,USBInput or wireless input, automatic detection of loom operation failure and classification statistics, automatic collection of each machine operation data, real-time understanding of the machine production situation (efficiency, output, scheduling, etc.), with network group control, remote control, online diagnosis and other functions. |

| Lubrication Cooling System | A closed forced circulation lubrication system driven by a separate oil pump motor is used to increase the electronic oil temperature monitoring and protection function to ensure that all moving parts are well lubricated and extend the life of the parts. |

| Color Selection | Stepping motor controlled rotary high-speed electronic weft selector, color selection mechanism can be equipped with up to16 Colors. |

| Fluffing Device | Electronic control Reed-type fluffing mechanism, the fluffing mechanism moves outward, easy to install and maintain, stable and reliable. The special power servo motor is used to drive the space connecting rod to control the precise positioning of the reed to realize the unique long and short weft beating of the towel loom, which can realize 3-7Weft arbitrary switch. The height of the loop can be set freely, and it can weave higher loop tissues such as wave hair and relief hair. The maximum weaving height of the loop is 12mm. Separate worm gear oil bath lubrication. |

| Let Off | The upper and lower sending boxes are inlaid in the small wall panel, which is convenient to install, eliminates the worm gear, reduces wear, and is more durable. |

| Take Up | Servo electronic coiling, which can realize variable weft density weaving. |

Previous

None

Next

Online consultation

No.5 Yingchun Road, Yanghe Town, Gaoming District, Foshan City, Guangdong Province

Copyright © Guangdong kingtex weaving equipment Co., Ltd

Business License