Technical Status of Rapier Loom

rapier loomWide adaptability, cost-effective, in the shuttleless loom occupies the largest proportion. analysis of the current domestic and foreignrapier loomThe technical level and development trend of rapier loom are analyzed and discussed, and some problems in the selection of rapier loom are analyzed and some suggestions are put forward for the application of rapier loom.

With China's accession to the WTO and the further deepening of the reform of the enterprise system, China's textile industry is facing unprecedented opportunities and challenges. The focus of competition will be the adjustment of product structure and the improvement of product grade and quality. The use of new technology to transform traditional handicrafts is the only way for the development of productive forces. Especially in science by leaps and bounds, the unprecedented speed of technological updates today. Therefore, the traditional textile industry must also undergo a step-by-step and thorough transformation. How to speed up the pace of technological progress and increase the proportion of China's shuttleless looms is the fundamental shortcut to solve the problem of high-grade products. This paper only takes the numerous rapier looms used in shuttleless looms at home and abroad as an example to illustrate their technical level and selection problems.

1 Overview

According to incomplete statistics, by the end of 2004, China had nearly 1.76 million looms of various types, including about 1.09 million shuttle looms, 1.03 million shuttle cotton looms and more than 675000 shuttleless looms. (Among them, 720000 projectile looms, 121000 rapier looms, 315000 simple GA74 series rapier looms and 85000 air-jet looms), the non-shuttle weaving machine rate is 24.83. GA74 series included)rapier loomis 38.24 per cent). GA611, GA615(1511, 1515) series of cotton looms are still widely used in the cotton weaving industry.

In the weaving industry, private enterprises have accounted for more than 2/3 of the whole industry through structural adjustment and system adjustment, and the proportion of shuttleless looms in coastal areas has accounted for more than half of the country, and the ability of products to adapt to the market has been improved. There are also a considerable number of enterprises have carried out joint ventures, restructuring and equipment upgrading, with the ability to produce high-grade fabrics on a large scale, and most of the products are exported. However, the country is still dominated by low-level production capacity, high-level production capacity is insufficient, products have not changed for many years, and the level of supporting and serialization is very insufficient.

2 At present, the technical level of rapier looms and supporting equipment at home and abroad.

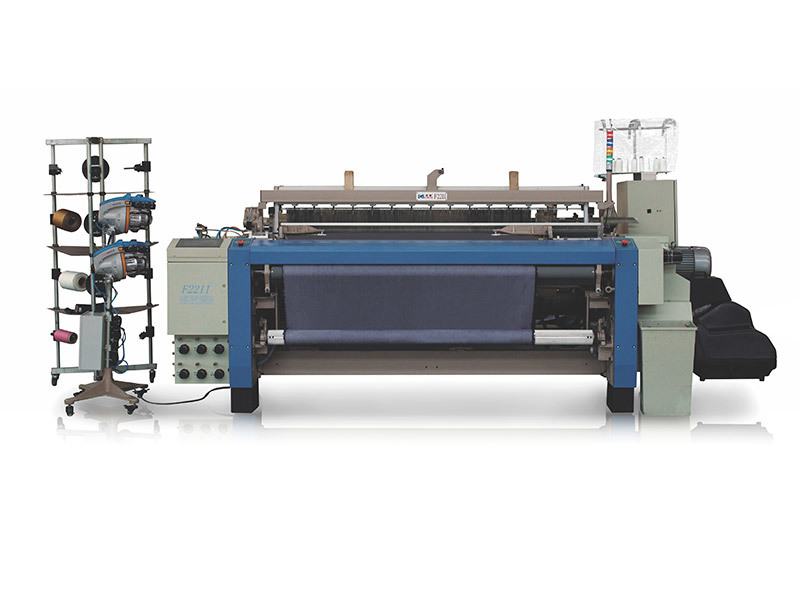

Among shuttleless looms, the rapier loom is the universal and most reliable loom for weaving small batch, medium batch and frequent color change fabrics. The price is lower than the projectile loom. In recent years, with the improvement of the weft insertion mechanism, the weft insertion speed has increased, but the acceleration change is relatively gentle; the structure of the rapier weft clamping movement can be applied to yarns of different materials and structures, and there is no need to exchange the sword between 0.7tex ~ 3300tex. The range of fabrics processed by rapier loom has developed from medium-thick fabrics to light and thin fabrics, from clothing fabrics to decorative and industrial fabrics, from single-layer fabrics to pile and double-layer pile fabrics, and from narrow width to 4.6 meters. Its breadth has developed from low speed to high speed. At present, the highest weft insertion speed of rapier loom has exceeded 1500 m/min, and the color selection of weft yarn has also developed from a single color to a maximum of 16 colors, and the adaptability of varieties is not as good as that of other shuttleless looms.

Rapier loom

Previous:

Next:

RELATED INFORMATION

Collaboration & Transformation: Leaders of China Textile Machinery Association Visit Kingtex Company

2025-11-28

2025-10-31

Invitation | Meeting You at the ITMA ASIA + CITME Singapore 2025 Exhibition

2025-10-13

No.5 Yingchun Road, Yanghe Town, Gaoming District, Foshan City, Guangdong Province

Copyright © Guangdong kingtex weaving equipment Co., Ltd