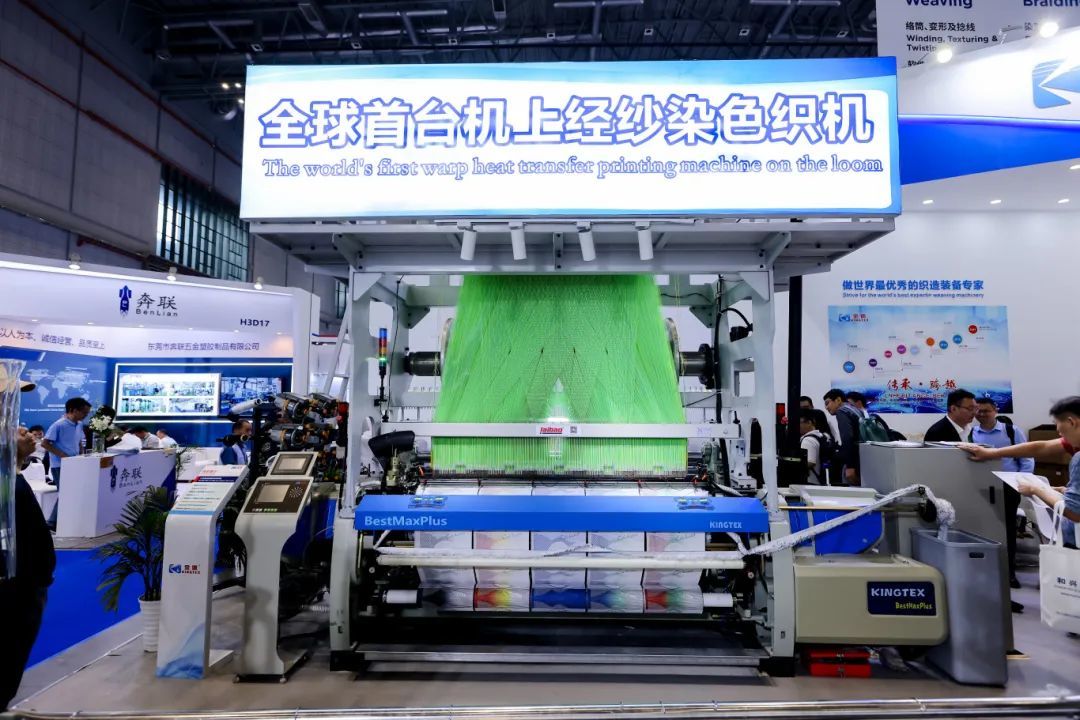

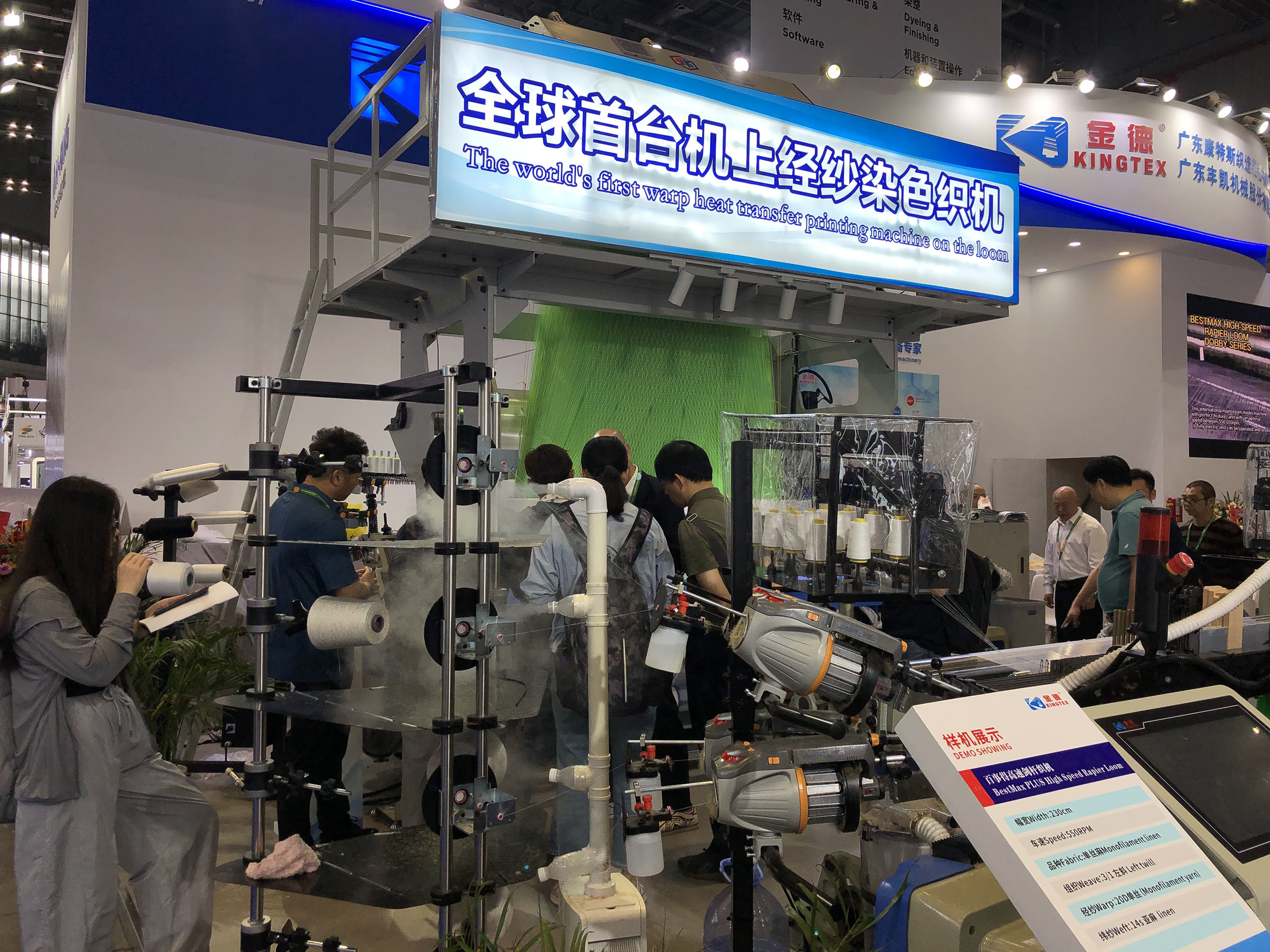

"The World's First Warp Heat Transfer Printing Machine On The Loom" Textile Industry Upgrade Essential Weapon

When the dyeing and weaving Shoe Upper first entered the market, it quickly spread in the industry at an amazing speed.

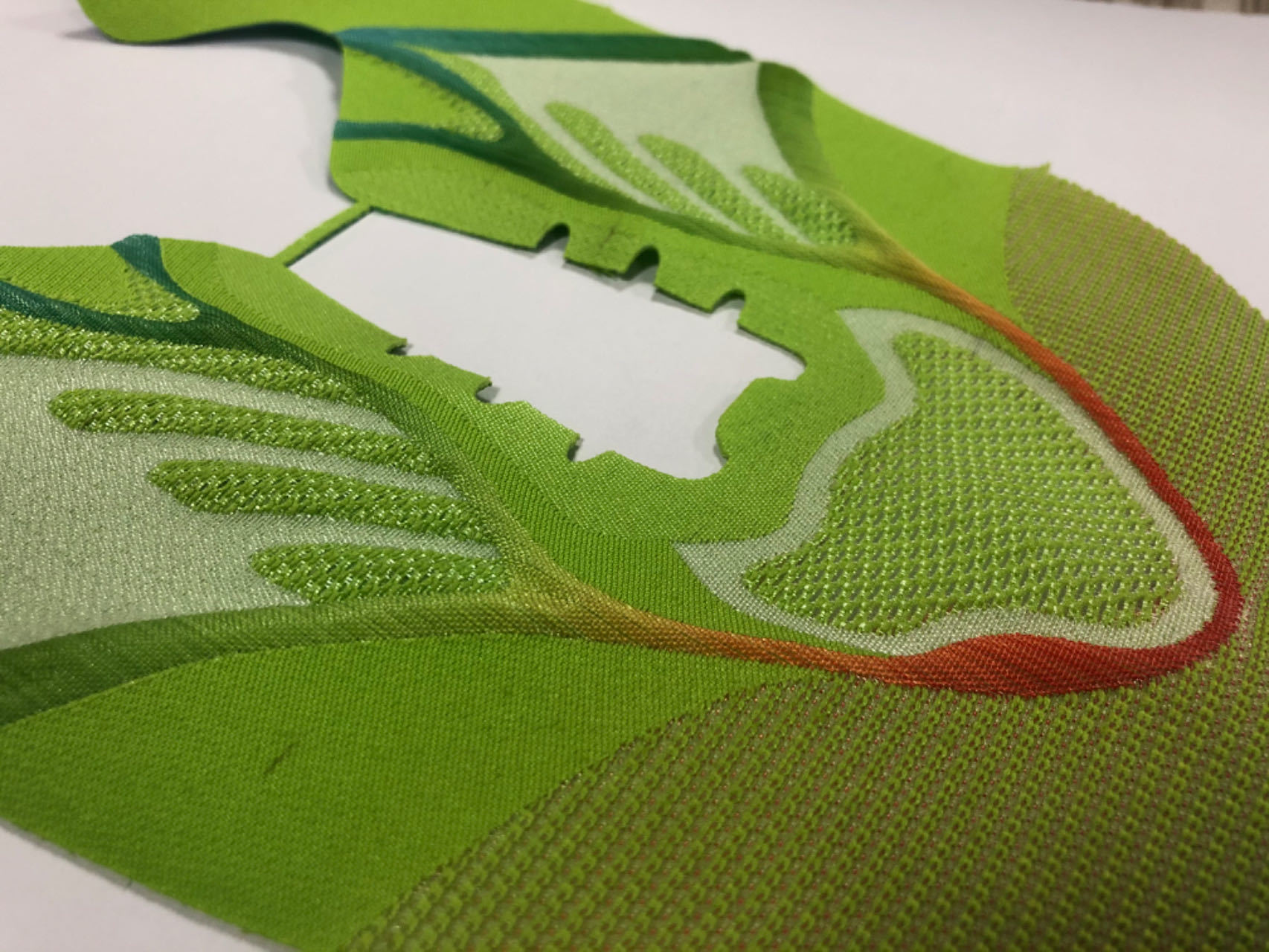

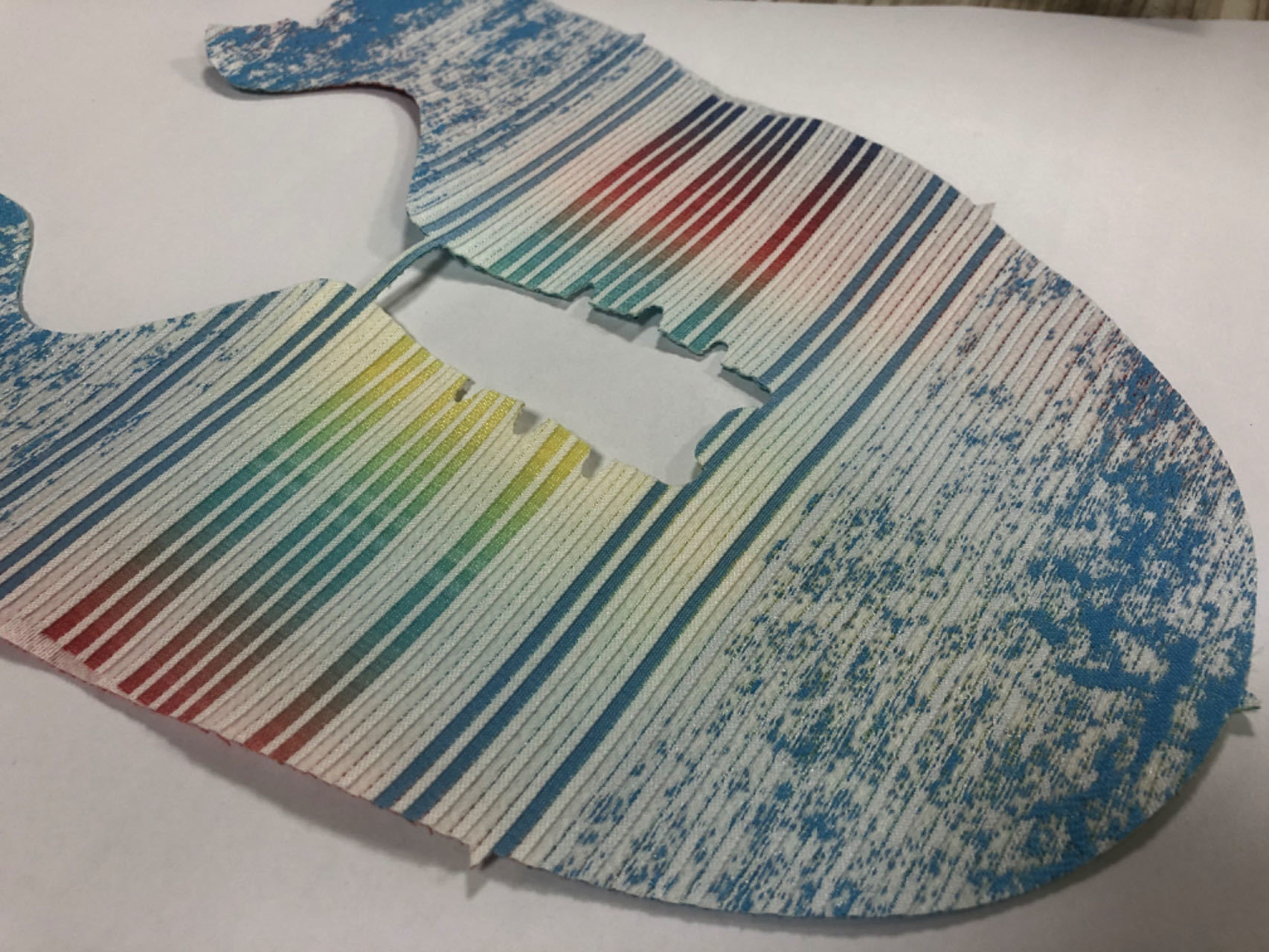

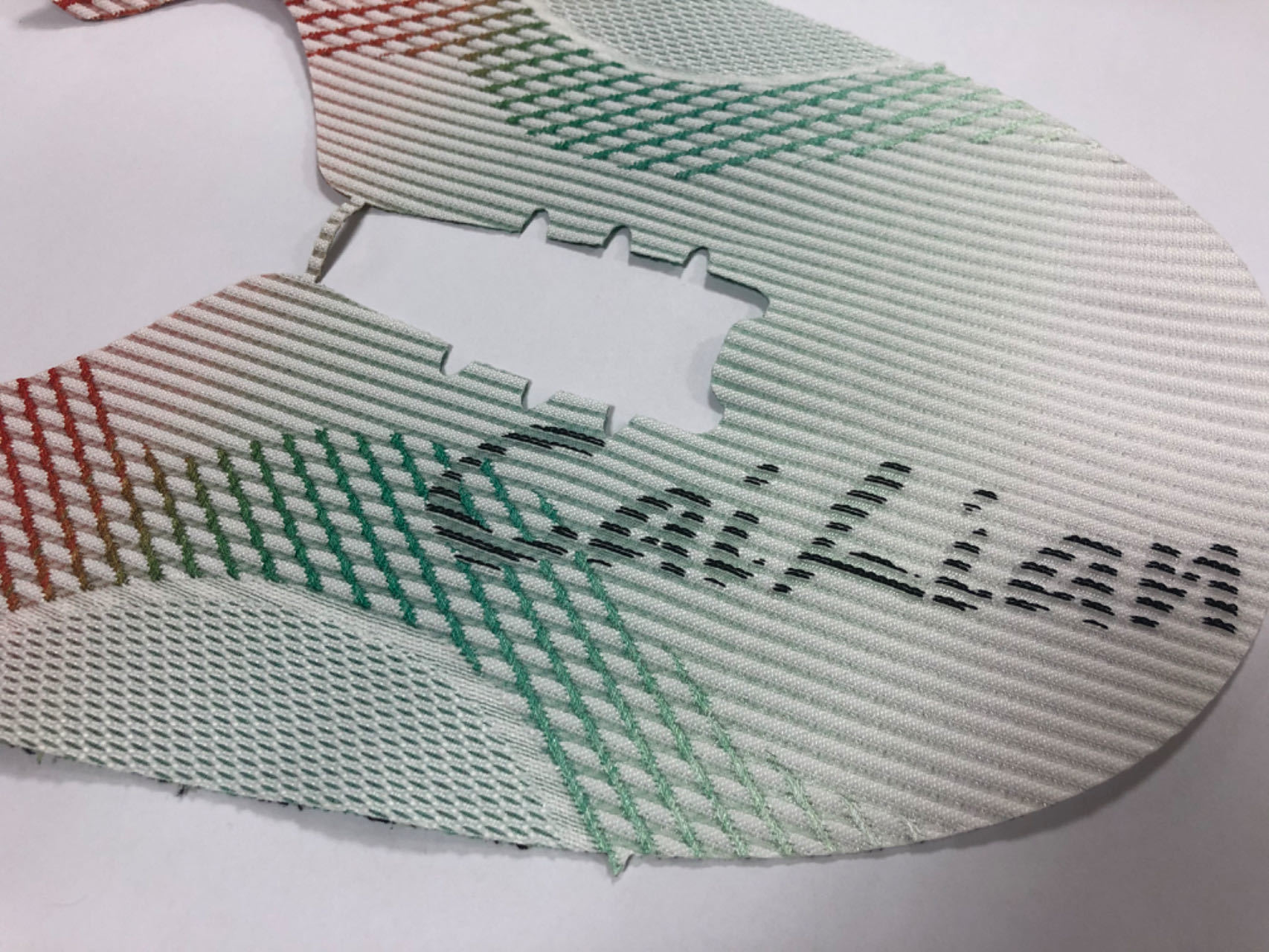

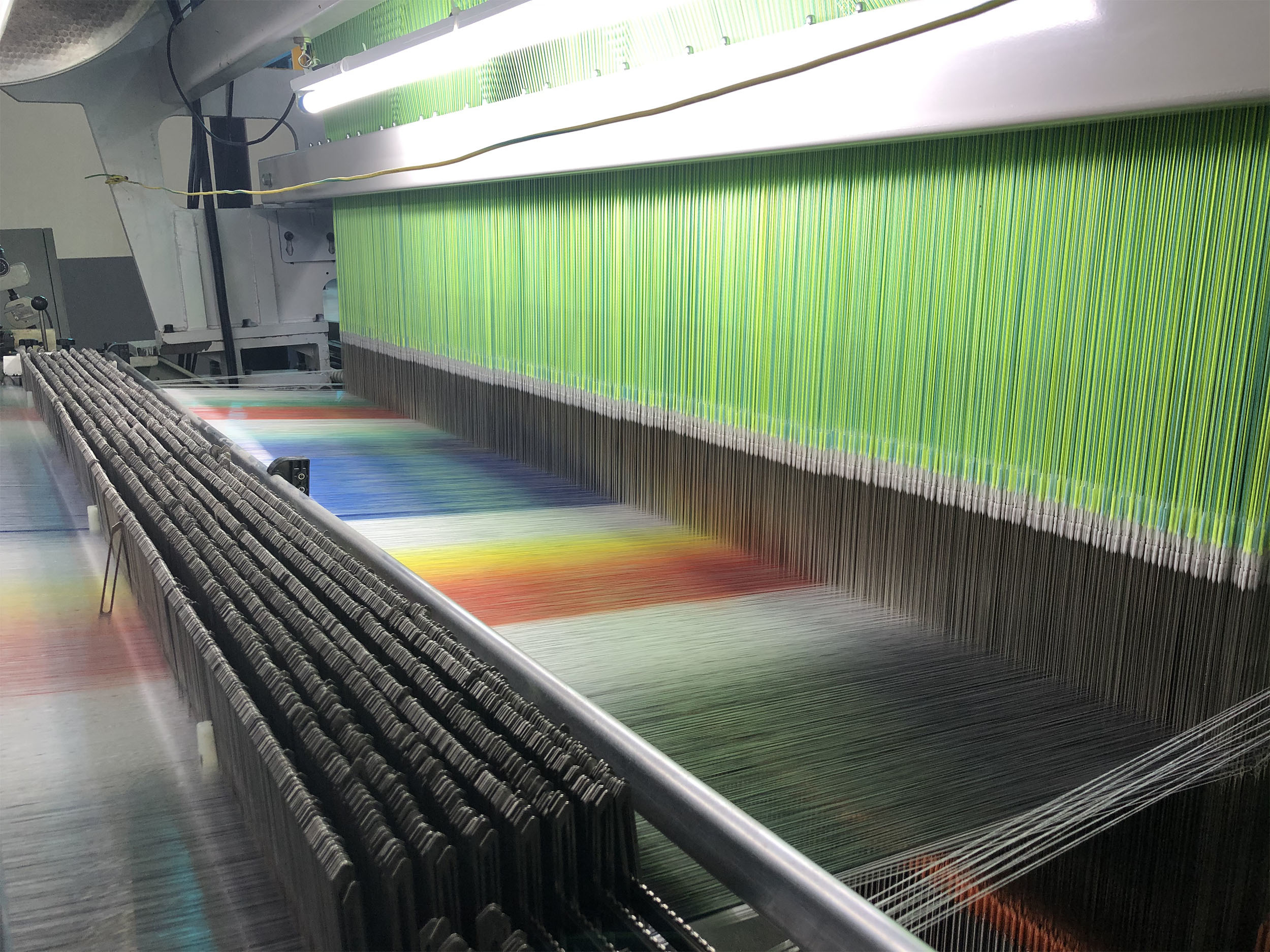

The surface of these products presents a sense of bumpy three-dimensional layer, bright colors and gradual natural, delicate and rough clever combination, for the brand to bring a visual feast.

Third Dimension |  Gradient and Layered |  Gradient and Layered |  Gradient and Layered |  Brand Customized |

All these achievements are due to the flexible shuttle of the warp through the structure, Under the action of setting temperature can impart the fabric with slight elasticity and under the help of the shearing machine can impart the fabric with perfect air permeability.

Unfettered |  Breathable |

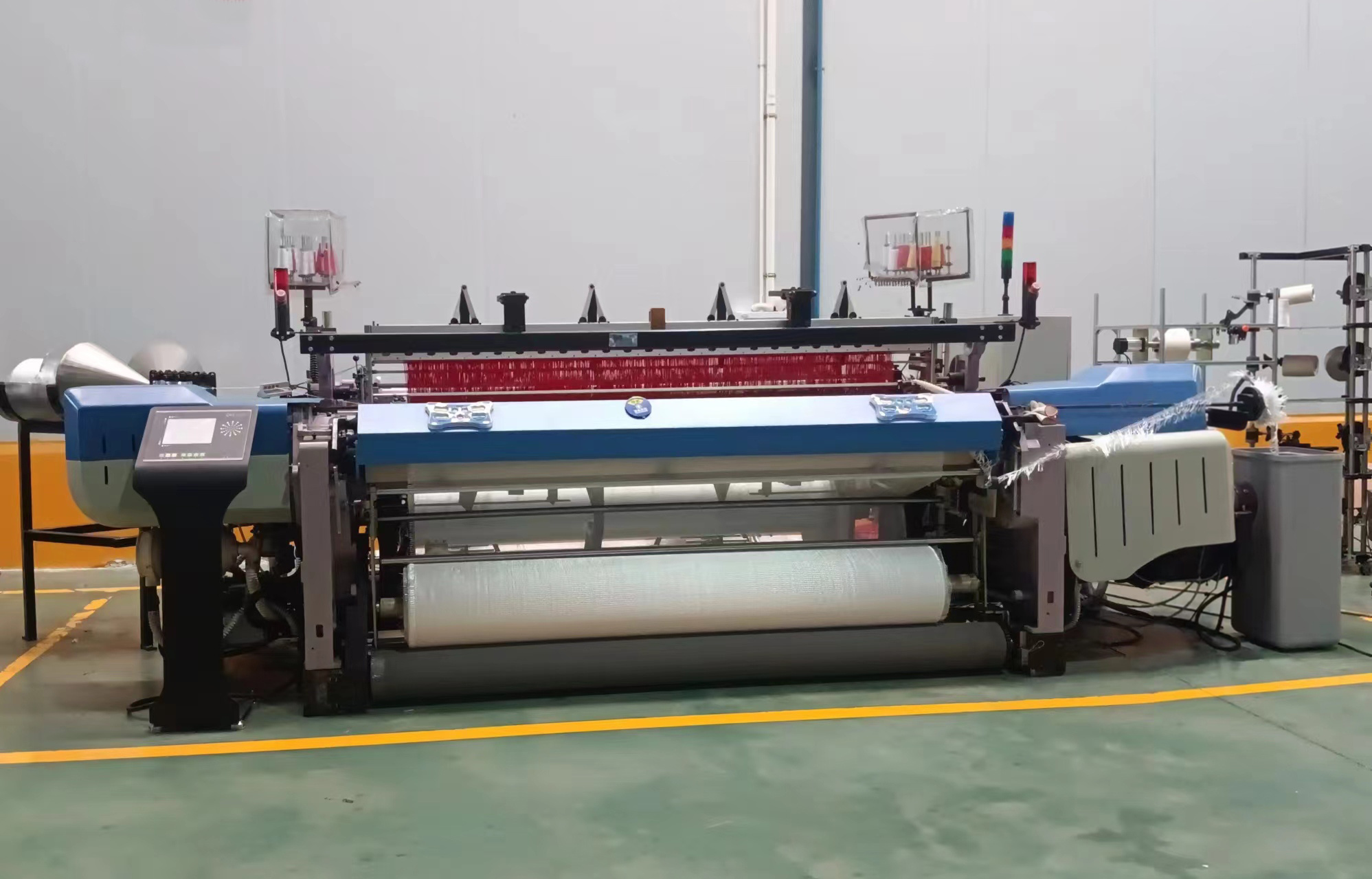

At ITMA ASIA + CITME 2024 Exhibition, With its unparalleled speed advantage, Kingtex's Shoe Upper dyeing weaving loom easily outperforms all existing looms. The speed increased directly reflects its value, causing production to soar and profits to rise with it. Despite the huge increased in speed, Kingtex weaving machine is still running smoothly and as steady as a rock. This is benefit from its loom body of 2.4 meters and the width of the shoe upper of 1.9 meters. The wide span enhance the stability of the center of gravity of the machine.

In addition, the close connection between the warp heat transfer printing machine and the weaving loom, as well as the weight of the warp heat transfer printing machine itself more than one ton, provides a solid support for the machine, further ensuring its stability and speed.

Since its foundation, Kingtex Weaving Machine has been responsible for the production of heavy fabrics on looms. The Kingtex Weaving Machine has unprecedented advantages in the production of heavy fabrics such as shoe uppers.

Industrial Fabric Weaving Loom Machine |  Denim Fabric Weaving Loom Machine |  Glass Fiber Leno Weaving Loom Machine |

Shoe Upper Jacquard Weaving Loom Machine |  Jacquard Weaving Loom Machine |  Label Jacquard Weaving Loom Machine |

At the same time, Kingtex Shoe Upper machine has never sacrificed product quality while reducing costs. In the key parts of the machine, such as the Full-width temple. A copper structure is used instead of the aluminum alloy widely used on the market. This is due to the fact that after prolonged use of aluminum alloy materials, the screws are easily unscrewed and can lead to breakage, as well as shoveling warp.

Kernel Component |  Copper Structure |

Kingtex dyeing and weaving machine uniquely conveys the concept of value, creates textile materials a dazzling shine, and also brings high profits to investors!

Kingtex Weaving Machines,Textile Machinery,Rapier Loom Machine,Shoe Upper Jacquard Dyeing Weaving Loom Machine,Kingtex Looms

RELATED INFORMATION

Salute to 2025, Embrace 2026 | Thanks to Every Fellow Traveler on This Journey

2025-12-31

Collaboration & Transformation: Leaders of China Textile Machinery Association Visit Kingtex Company

2025-11-28

2025-10-31

No.5 Yingchun Road, Yanghe Town, Gaoming District, Foshan City, Guangdong Province

Copyright © Guangdong kingtex weaving equipment Co., Ltd